Laboratories have proven to be a vital resource to society. Not only do lab professionals perform important research with the aid of analytical instruments to make new discoveries, but they also provide data-driven insight to companies and governments so they can make informed decisions. All that said, laboratories and their staff are only as productive and efficient as their equipment allows. While a lab’s equipment can be the thing that holds efficiency and productivity back, people could also be the reason. Lab techs are intelligent individuals with years of education and, in some cases, experience, but that doesn’t mean they don’t make mistakes. The most common mistakes in laboratories are equipment-related—specifically, the incorrect operation and maintenance of the instruments. We understand the importance of analytical instruments in the research process, and most labs don’t have time to waste. Every lab can improve efficiency somewhere, and one way to improve is by avoiding the most common mistakes in gas chromatography. Continue reading our comprehensive guide below to learn more.

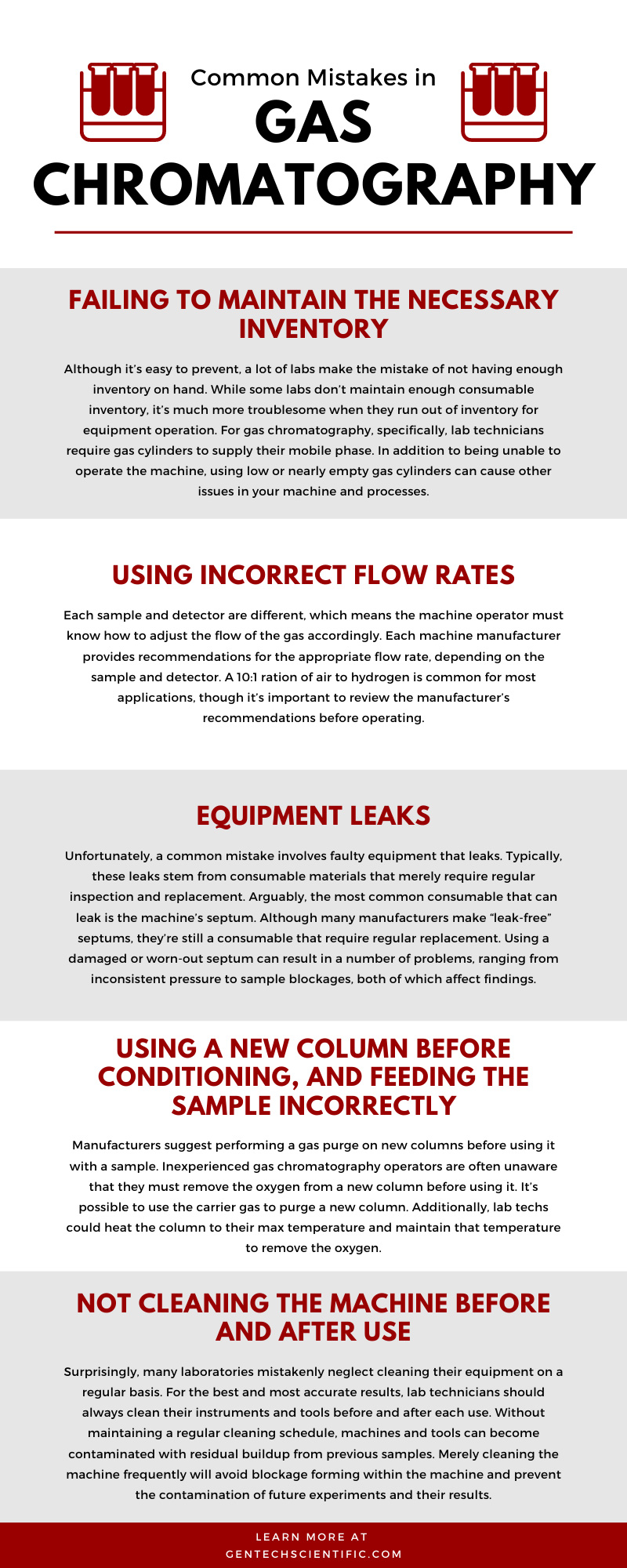

Failing to Maintain the Necessary Inventory

Although it’s easy to prevent, a lot of labs make the mistake of not having enough inventory on hand. While some labs don’t maintain enough consumable inventory, it’s much more troublesome when they run out of inventory for equipment operation. For gas chromatography, specifically, lab technicians require gas cylinders to supply their mobile phase. In addition to being unable to operate the machine, using low or nearly empty gas cylinders can cause other issues in your machine and processes. As the components of a gas cylinder decrease, the risk of contaminants reaching your machine and sample increases. If contaminants enter the machine, there’s a higher chance that it will require deep cleaning, resulting in downtime. In some cases, the contaminants could damage internal components of the machine, requiring repairs and prolonged downtime.

Using Incorrect Flow Rates

Each sample and detector are different, which means the machine operator must know how to adjust the flow of the gas accordingly. Each machine manufacturer provides recommendations for the appropriate flow rate, depending on the sample and detector. A 10:1 ration of air to hydrogen is common for most applications, though it’s important to review the manufacturer’s recommendations before operating. It’s also important that the machine and the detector properly warm up before analysis begins. If the detector doesn’t reach the appropriate temperature before the examination begins, it could weaken the findings and results.

Equipment Leaks

Unfortunately, a common mistake involves faulty equipment that leaks. Typically, these leaks stem from consumable materials that merely require regular inspection and replacement. Arguably, the most common consumable that can leak is the machine’s septum. Although many manufacturers make “leak-free” septums, they’re still a consumable that require regular replacement. Using a damaged or worn-out septum can result in a number of problems, ranging from inconsistent pressure to sample blockages, both of which affect findings. In addition to wearing out, a septum may also leak if it’s the wrong size for the machine. Prior to replacing a septum, it’s best to reference the machine’s manual for the required specifications. While replacing consumables such as the septum often fixes leaks, there may be another component leaking. The machine’s inlet is another common place to find leaks. Following a regular cleaning and maintenance schedule is the best way to prevent inlet leaks going forward.

Using a New Column Before Conditioning, and Feeding the Sample Incorrectly

Manufacturers suggest performing a gas purge on new columns before using it with a sample. Inexperienced gas chromatography operators are often unaware that they must remove the oxygen from a new column before using it. It’s possible to use the carrier gas to purge a new column. Additionally, lab techs could heat the column to their max temperature and maintain that temperature to remove the oxygen. Another mistake that new lab technicians might make is to inject the sample incorrectly. They may do this by injecting the sample too quickly or by using the wrong syringe. If the sample overwhelms (or floods) the machine’s liner, the data will likely include unexplained spikes because of gas volumes and sample vapor. Moreover, an overwhelmed liner makes the experiment nearly impossible to replicate going forward. Typically, the cause of a flooded liner is the result of the lab technician using a large volume syringe when the sample required less volume.

Not Cleaning the Machine Before and After Use

Surprisingly, many laboratories mistakenly neglect cleaning their equipment on a regular basis. For the best and most accurate results, lab technicians should alwaysclean their instruments and tools before and after each use. Without maintaining a regular cleaning schedule, machines and tools can become contaminated with residual buildup from previous samples. Merely cleaning the machine frequently will avoid blockage forming within the machine and prevent the contamination of future experiments and their results.

Using Outdated Analytical Instruments

Nearly every industry in recent decades has seen tremendous innovation, and the lab equipment industry is no different. That said, some laboratories have failed to adopt the innovations for their own lab. While many labs don’t need the latest available instruments, they do need to update their equipment from machines that are beyond outdated. Analytical instruments are a lab’s path to successful research, and a laboratory’s equipment shouldn’t keep them from progressing and improving that research. Outdated equipment is unable to support and replicate the experiments that that labs around the world are regularly performing.

As you can see, there are a lot of common mistakes made in gas chromatography that can significantly hold your lab back from progressing in meaningful work. Many of these mistakes are easy to prevent with training and effective policies and procedures. Though, if you’re still using equipment that you purchased decades ago, your equipment is likely preventing your lab from making progress and holding back your productivity and efficiency. If the previous scenario describes your lab, it’s time to upgrade your analytical instruments for the sake of science. We know you’re probably concerned about the cost of upgrading, but upgrading doesn’t have to break the bank, either.

Purchasing refurbished lab equipment from GenTech Scientific is the best way to upgrade your equipment. The people we have refurbishing our equipment are industry experts with extensive experience, which allows us to guarantee top-quality products. Our impeccable refurbishing process involves in-depth inspections where we repair or replace any malfunctioning parts. When a machine leaves the hands of our servicers, it goes through rigorous testing protocols to ensure it meets the manufacturer’s standards and will exceed your expectations. If you’re looking for a gas chromatography machine for sale or any other analytical instruments, we’ve got you covered. If you’d like to request pricing, discuss financing, or sell or trade your old equipment, contact our team today. We look forward to working with you.