We live in a society where there’s a medicine for almost anything, hence the rise in Big Pharma, increased research, and consistent growth in pharmaceutical employment. All these patterns beg the question: how do pharmaceutical professionals conduct research and safely manufacture medicine? One factor that plays a major role is chromatography and its different types. In fact, chromatography also helps ensure safe products because the process allows lab technicians to separate mixtures into their purest state. However, there are more applications of chromatography in the pharmaceutical industry. Continue reading to learn more.

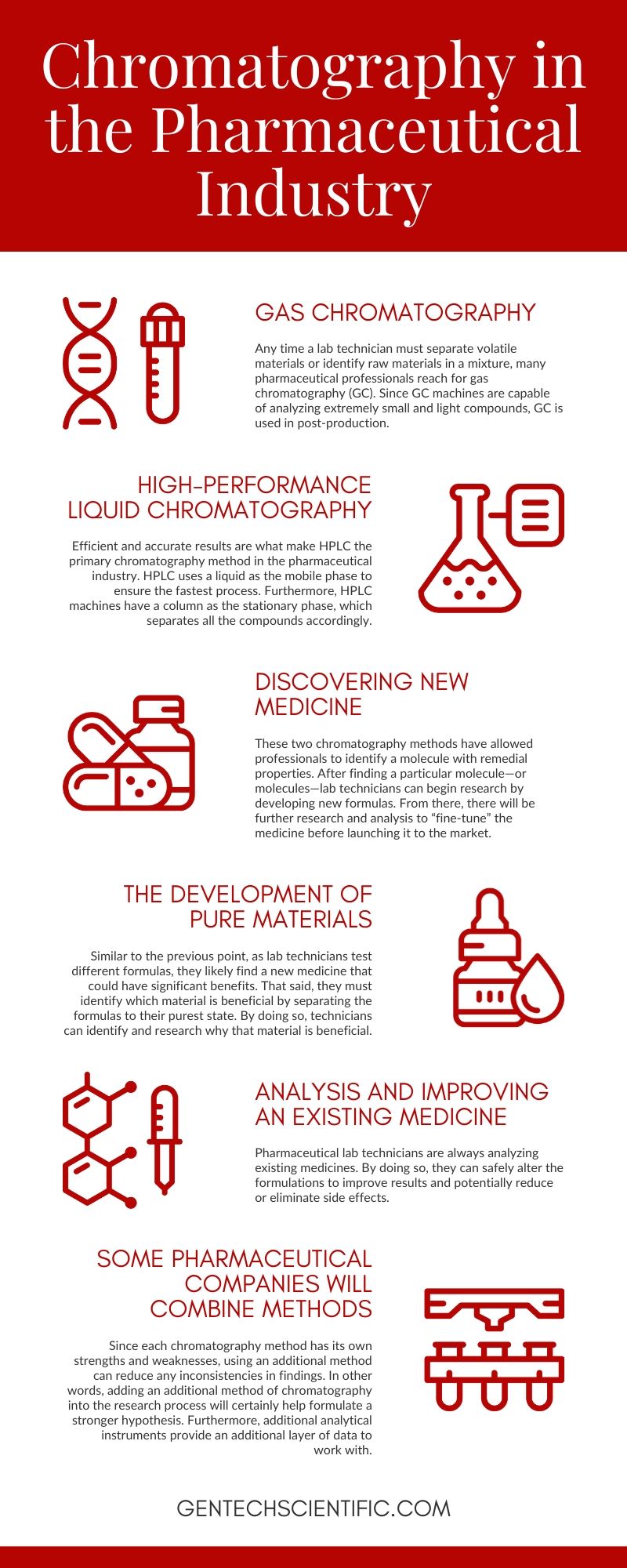

Gas chromatography

Any time a lab technician must separate volatile materials or identify raw materials in a mixture, many pharmaceutical professionals reach for gas chromatography (GC). Since GC machines are capable of analyzing extremely small and light compounds, GC is used in post-production. In other words, GC is a standard process during quality control. However, identifying volatile impurities is the primary use for GC within the pharmaceutical industry.

High-performance liquid chromatography

The most common chromatography methods used in the pharmaceutical industry are both liquid chromatography (LC) and high-performance liquid chromatography (HPLC). However, efficient and accurate results are what make HPLC the primary chromatography method in the pharmaceutical industry. HPLC uses a liquid as the mobile phase to ensure the fastest process. Furthermore, HPLC machines have a column as the stationary phase, which separates all the compounds accordingly.

If there is ever an issue with a particular medicine, locating the problem as quickly as possible is vital to the health of patients. HPLC machines offer several benefits, two of which are efficiency and ease of use. These machines allow lab technicians to work quickly, without requiring excessive training. As long as the operator follows the initial process, the machine will handle the rest.

Discovering new medicine

These two chromatography methods have allowed professionals to identify a molecule with remedial properties. After finding a particular molecule—or molecules—lab technicians can begin research by developing new formulas. From there, there will be further research and analysis to “fine-tune” the medicine before launching it to the market. Of course, launching a new pharmaceutical into the market is not that simple. Each and every pharmaceutical company is held to an extremely high standard by the FDA, which leads to its own complications and, of course, further research.

The development of pure materials

Similar to the previous point, as lab technicians test different formulas, they likely find a new medicine that could have significant benefits. That said, they must identify which material is beneficial by separating the formulas to their purest state. By doing so, technicians can identify and research why that material is beneficial. From here, pharmaceutical professionals can make educated arguments for their hypothesis, and potentially launch a new pharmaceutical drug.

Analysis and improving an existing medicine

To reiterate, there seems to be a pill for almost anything on the market nowadays. That said, pharmaceutical lab technicians are always analyzing existing medicines. By doing so, they can safely alter the formulations to improve results and potentially reduce or eliminate side effects. However, in order to properly analyze a product that a patient would receive, lab techs must reverse the process and work backward in order to analyze the final product. Using chromatography––typically HPLC––is one of the steps in a several step process.

Alternatively, the worst-case scenario for any pharmaceutical company is issuing a recall. Once the company and the FDA decide to pull the pharmaceutical drug from the market, the research and analysis begin. However, time is not on their side for several reasons. First, the company answers to shareholders, and those individuals typically expect profit over anything else. Second, even with side effects, many patients depend on the medicine for their wellbeing. All that said, lab technicians need to analyze the recalled medicine as quickly as possible. To find a solution efficiently, pharmaceutical companies will often rely on HPLC, as it’s the fastest method to get a result.

Some pharmaceutical companies will combine methods

While this isn’t as common, especially when finding a solution to a recall, combining chromatography methods can be helpful. Since each chromatography method has its own strengths and weaknesses, using an additional method can reduce any inconsistencies in findings. In other words, adding an additional method of chromatography into the research process will certainly help formulate a stronger hypothesis. Furthermore, additional analytical instruments provide an additional layer of data to work with. In fact, mass spectrometry (MS) has become an increasingly popular tool to use during research and analysis, and it would be unwise to refrain from having an MS machine on hand.

In Conclusion…

The bottom line is that laboratories are held to an extremely high standard, and they’re responsible for every product that leaves their testing facilities. However, because of the nature of the industry and the societal effect of medicine, pharmaceutical labs are held to an even higher standard. Luckily, pharmaceutical companies recognize these standards and do everything in their control to meet them. That includes having quality lab equipment to meet the demands, standards, and research requirements to be a successful pharmaceutical company. Luckily, there are ways for companies to update their lab equipment that will benefit the company, shareholders, and most importantly, the end-users.

At GenTech Scientific, we understand the critical role chromatography plays in the pharmaceutical industry. As a trusted supplier of expertly refurbished lab equipment, we provide high-quality GenTech-certified instruments restored to near-factory condition—at a fair price. Our in-house team handles every refurbishing step, ensuring personalized support and exceptional reliability. With over 30 of experience, we take pride in helping our customers succeed by delivering equipment they can trust. If your lab is considering an upgrade, refurbished equipment offers a cost-effective, dependable alternative to new instruments. Contact us today to learn how we can support your laboratory needs.