What to keep near your LC at all times!

1

Gloves!

Always prepare mobile phases using clean, powder-free nitrile gloves to minimize the risk of lipid, salt, and surfactant contamination. Avoid touching solvent inlets, column fittings, and LC sample vials with bare hands for the same reason.

2

1/4-inch Wrenches

Many metal LC lines and column fittings use a ¼ in. wrench, so keeping one nearby is highly recommended. When tightening metal fittings, use two wrenches—one to stabilize the column or valve body and one to tighten the fitting. Note that some fittings may require different wrench sizes or be finger-tight, depending on the manufacturer and fitting type.

3

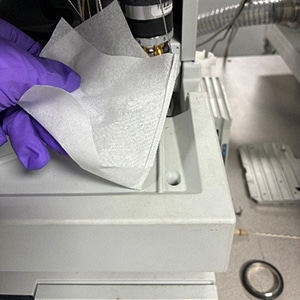

KimWipes®

Many metal LC lines and column fittings use a ¼ in. wrench, so keeping one nearby is highly recommended. When tightening metal fittings, use two wrenches—one to stabilize the column or valve body and one to tighten the fitting. Note that some fittings may require different wrench sizes or be finger-tight, depending on the manufacturer and fitting type.

4

Replacement Filters/Frits

If mobile phase delivery or system pressure becomes inconsistent, the solvent inlet frit may be partially blocked and require replacement. Inlet frits prevent particulates from entering the pump and should be inspected or replaced as part of routine preventive maintenance, especially when using buffered or particulate-prone solvents.

5

Spare Tubing

A contaminated or degraded line can contribute to increased baseline noise, peak broadening, and retention time variability. Stainless steel or PEEK tubing may be used for pre- and post-column connections, depending on pressure, solvent compatibility, and analyte sensitivity. Always verify the required tubing inner diameter (ID), particularly post-column, to minimize extra-column volume and preserve chromatographic performance.

6

PEEK Fittings

Standard PEEK fittings are designed to be finger-tight only. Overtightening can deform the ferrule or crimp the tubing, leading to leaks and poor reproducibility. Although some fittings may appear to require a wrench, tools should not be used unless explicitly specified by the manufacturer.

7

Unions

When cleaning or flushing the LC system, installing a union in place of the column allows solvent to pass through the pump, injector, detector, or MS inlet without exposing the column. This is a recommended practice for purging buffer salts or strong solvents that could otherwise reduce column lifetime.

8

Caps (Solvent Reservoir Caps)

To keep mobile phases clean, solvent reservoirs should be covered at all times using clean, tightly fitting caps with dedicated ports for solvent inlet tubing. Properly vented caps reduce particulate and atmospheric contamination while allowing stable solvent delivery.

9

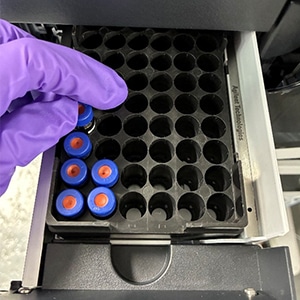

LC Vials with the Proper Caps

Standard LC autosampler vials typically have a nominal volume of approximately 2 mL and are used with caps containing septa or pre-slit liners that allow needle penetration while minimizing atmospheric exposure. Although vials can technically be reused, reuse is generally discouraged due to the risk of cross-contamination and analyte carryover in sensitive LC methods.

10

Large Plastic Syringe

A large plastic syringe is useful for priming solvent lines and removing trapped air during solvent changes. Eliminating air helps prevent pump cavitation and unstable flow, which can negatively affect overall system performance and downstream components.

11

Phillips Head Screwdriver

If you are willing to venture into your instrument further, a Phillips head screwdriver is always useful for removing instrument covers or access panels. Users should limit tool use to manufacturer-approved procedures, as internal servicing of pumps, detectors, or electronics is typically restricted to trained service personnel.

12

Lastly, the phone number to your service engineer!

Maintaining access to your service engineer and enrolling in a preventive maintenance service contract is strongly recommended. Routine professional maintenance helps prevent prolonged system damage, minimizes downtime, and supports the long-term reliability of LC instrumentation.

Call GenTech Scientific at (585) 492-1068 for service and for service contract options to limit downtime and extend the overall lifetime of your LC!

Prefer to watch a video?

More resources:

- Browse our #TechTipTuesday videos on YouTube.

- TECH TIP: Overcoming LC/MS Challenges

- TECH TIP: HPLC Column Selection

- Tips for Optimizing High-Performance Liquid Chromatography (HPLC)

- TECH TIP: Troubleshooting Your HPLC System

- TECH TIP: How to Run Mass Analysis Using LC/MS

- The Difference Between GC/MS and LC/MS Systems

- A Quick Look at the Different Types of HPLC Testing