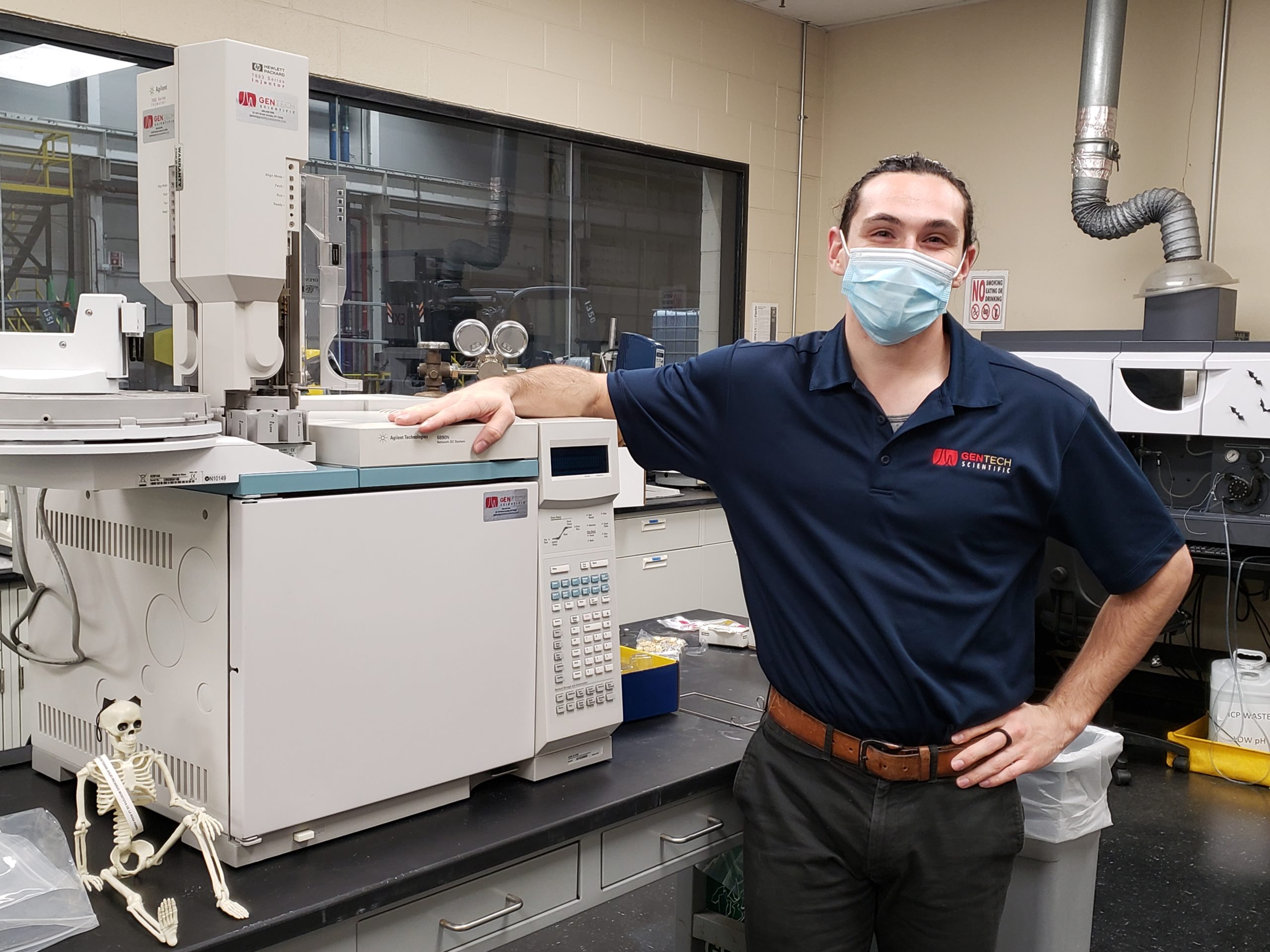

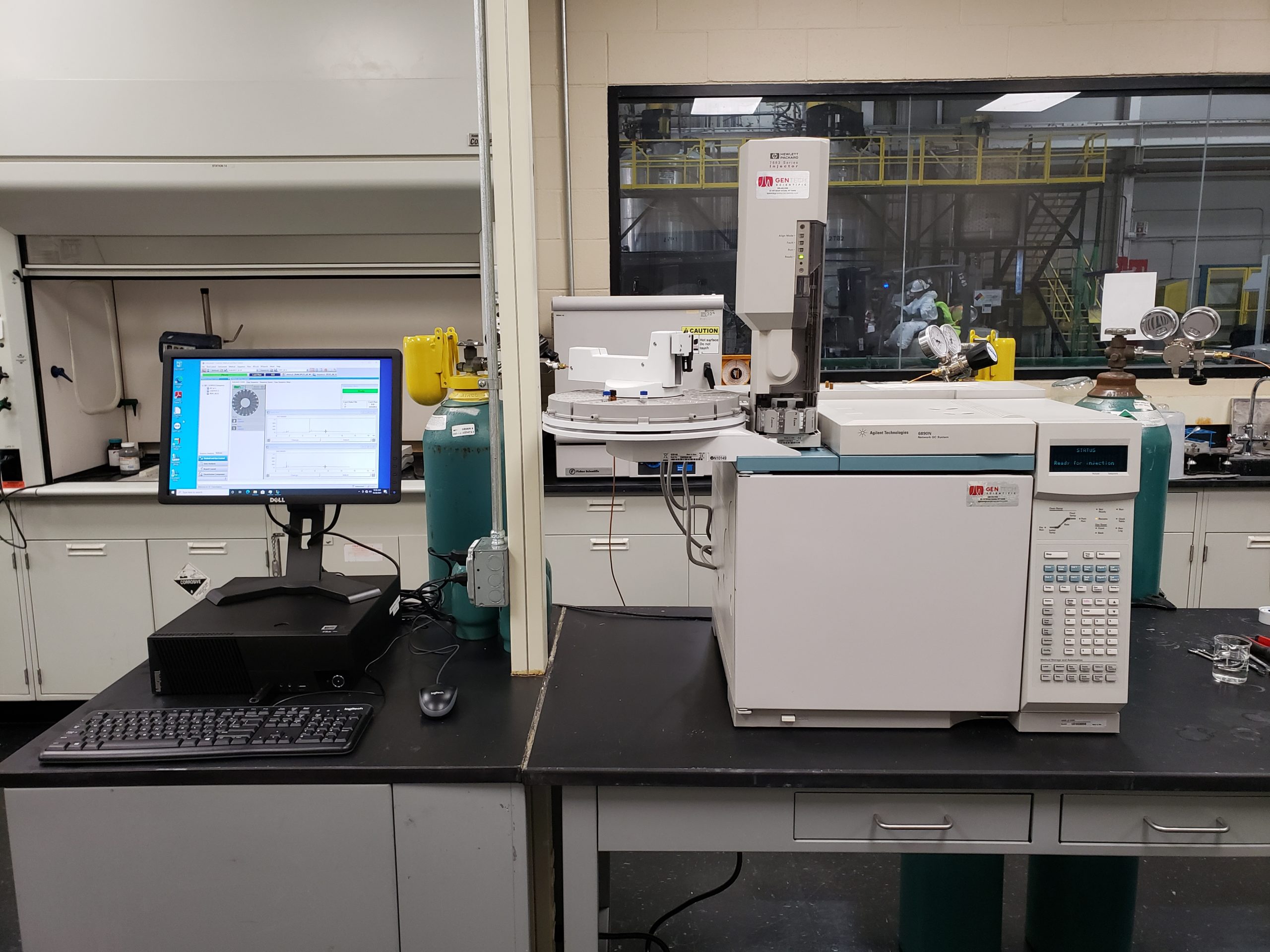

GenTech’s Process Improvement Leader, Joseph Bragg, went to Texas late last month to install a GenTech refurbished Agilent 6890 GC with dual towers, split/splitless injectors, and FID.

Upon his return from the successful installation, we talked with Joe about the installation, and asked about any insights or key takeaways that we could share with Tech Tips Tuesday readers.

Tech Tips: Joe, give us a little overview of what’s involved in an installation like this?

Joe: There’s a lot of preparation and post-service follow up on our end. But probably most relevant to Tech Tips readers are the on-site services we provide, such as confirming site preparation, unpacking the order, installing the gas plumbing, installing the electrical cabling, installing the instrument and data system, running the on-site performance confirmation, and providing a familiarization and training session.

Tech Tips: As we know, even the most successful installations encounter a few challenges. Can you pull any Tech Tips from your experience?

Joe: There were two things that happened that could apply to almost any installation. The first has to do with site preparation. Even though we employ a Site Prep Checklist and follow up with a phone confirmation with the customer, we still made a mistake not having the gas lines run to the instrument space already.

Tech Tips: So, the key takeaway here is that, if we can accurately confirm that step with the customer it will prevent unnecessary delay once our service engineer is on site.

A visual representation of the Site Prep Checklist:

Infographic: Site Preparation Checklist

Click the link above for larger view

Tech Tips: That’s a good tip. What was the second thing?

Joe: Within Chemstation, I could not get my reports to correctly display because a teeny-tiny checkbox got unchecked, causing about two hours of setback. This was despite my advance preparation to refamiliarize myself with the software. And this familiarization is, of course, equally important for the operators.

The key takeaways here are that when you’re not fully versed and consistently using instrument software you can easily overlook simple setbacks; and that on-site familiarization and training for the end users is critical as well, to reduce the need for troubleshooting and technical support in the long-term.

Tech Tips: Thanks for these insights, Joe. Any last thoughts you’d like to share?

Joe: The installation took place from Oct. 27-29. Since it was the Friday before Halloween, there were some costumes on-site. The two staff I had been working with had plans to dress up, and they included me. They were great customers to work with.

Disclaimer: When it comes to costume-wearing, please note that

past performance does not guarantee future results. 🙂