A powerful analytical technique, high-performance liquid chromatography (HPLC) is used to separate, identify, and quantify compounds in a sample. HPLC is widely used in the pharmaceutical industry for drug development and quality control, in the food industry for testing food safety, for environmental testing (air, water and soil), for cannabis profiling and screening for toxins and pesticides, and in forensic toxicology analyses.

How Does HPLC Work?

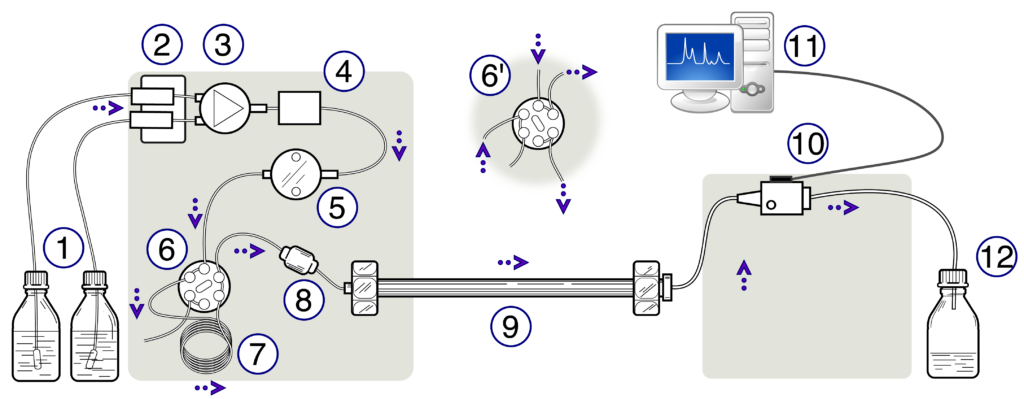

Schematic representation of an HPLC unit. (1) Solvent reservoirs, (2) Solvent degasser, (3) Gradient valve, (4) Mixing vessel for delivery of the mobile phase, (5) High-pressure pump, (6) Switching valve in “inject position”, (6′) Switching valve in “load position”, (7) Sample injection loop, (8) Pre-column (guard column), (9) Analytical column, (10) Detector (i.e. IR, UV), (11) Data acquisition, (12) Waste or fraction collector.1

HPLC works by passing a sample through a column filled with an adsorbent material that separates the components of the sample based on their physical and chemical properties. The separated compounds are then detected using detectors such as UV-Vis spectrophotometers or mass spectrometers. Sample preparation is an important step before performing HPLC analysis, as it ensures that all components of the sample are properly dissolved and ready for analysis.

HPLC Troubleshooting Basics

As scientists and laboratory technicians, it is crucial to have a comprehensive understanding of troubleshooting procedures for this widely used analytical system. This guide aims to provide you, as experts in the field, with a step-by-step troubleshooting process to help identify and resolve common problems encountered during HPLC analysis. Remember to consult your instrument manual or contact the manufacturer for further assistance if needed.

1. Initial Checks:

- Ensure that the power supply to the HPLC instrument is properly connected and turned on.

- Check the status of all indicator lights and displays on the instrument’s control panel.

- Verify that the mobile phase and all necessary solvents are properly prepared and available.

- Examine the tubing and connections for leaks or damage.

2. Baseline and Detector Issues:

- Inspect the detector flow cell for air bubbles or particles that may obstruct the light path.

- Check the detector’s wavelength settings to ensure they are appropriate for your analysis.

- Optimize the baseline by performing a baseline correction or adjusting the detector’s sensitivity settings.

- If the baseline noise is high, check for loose electrical connections or faulty signal cables.

- If you are using a UV detector, verify that the lamp is functional and replace it if necessary.

3. Pump Problems:

- Verify that the pump is properly primed and that the mobile phase is flowing through the system.

- Check the pump’s pressure and flow rate settings to ensure they are within the desired range.

- If the pump is not delivering the expected flow rate, inspect the tubing for blockages or air bubbles.

- Clean or replace the pump seals if there are leaks or irregular pressure fluctuations.

- Ensure that the pump’s solvent reservoirs are adequately filled.

4. Column Issues:

- Check the column connections to ensure they are tightly secured and free from leaks.

- Inspect the column for signs of damage, such as cracks or clogs, and replace if necessary.

- If the column pressure is high, check for blockages in the column or guard column.

- Verify that the column temperature is stable and appropriate for your analysis.

5. Autosampler Malfunctions:

- Confirm that the autosampler is properly loaded with samples and vials.

- Check the injection volume settings to ensure they match your intended analysis.

- Clean or replace the autosampler needle if it is clogged or bent.

- Ensure that the autosampler rack and tray are properly aligned, and there are no obstructions.

6. Software and Data Issues:

- Restart the HPLC software and ensure that the correct instrument is selected.

- Verify that the data acquisition parameters, such as injection volume and run time, are set correctly.

- Check the method parameters, such as column temperature and gradient program, for accuracy.

- If there are issues with data acquisition or integration, examine the chromatogram settings.

- Ensure that the computer running the HPLC software is not experiencing connectivity or hardware problems.

Troubleshooting HPLC instrumentation issues is an essential skillset for maintaining smooth analytical operations. By following the steps outlined in this guide, you can efficiently diagnose and address common problems encountered with HPLC systems. Remember to consult the instrument manual or contact GenTech Scientific’s service team of engineers and chemists. Regular maintenance, calibration, and adherence to proper usage practices can also help prevent future problems with your HPLC system, ensuring accurate and reliable analytical results.

More Resources

- Differences Between HPLC and GC Techniques

- How HPLC is Used in the CBD Potency Testing Process

- How is HPLC Used in Cleanliness Testing?

- A Brief Overview of PDA Detectors in HPLC

- A Quick Look at the Different Types of HPLC Testing

Footnotes

1 Image credit: This W3C-unspecified vector image was created with Inkscape – Own work. Legend based on : Practical High-performance Liquid Chromatography by Veronika Meyer, 4th edition, John Wiley and Sons, 2004, ISBN 0470093781, p. 7. and chromatography-online.org. Used file : Computer n screen.svg (Crystal SVG icons)., CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=5722928