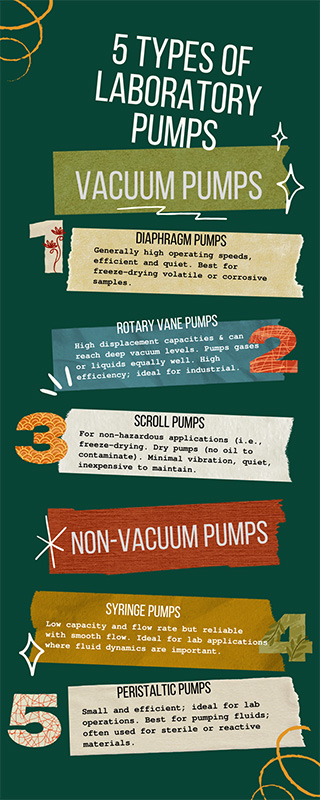

When it comes to selecting a pump for your laboratory, there are several important factors to consider. The right pump can greatly impact the efficiency and accuracy of your laboratory experiments and processes. Below are some key factors to consider when choosing a pump for your laboratory.

1. Consider Your Applications and Instrumentation

First and foremost, you need to assess the specific requirements of your applications and laboratory instrumentation.

- Consider the specific tasks the pump will be used for (e.g., fluid transfer, filtration, vacuum generation, chemical dosing, circulation, etc.). Only a modest vacuum is needed to move liquids. Evaporative applications require greater vacuum and must achieve the vapor pressure of the specific solvent used. The deepest vacuum level is required for freeze drying and molecular distillation applications.

- Consider the type of fluids involved (e.g., liquids, gases, corrosive chemicals, solvents). Consider the flow rate, pressure range, and chemical compatibility of pump materials with the fluids or gases you will be working with.

- For applications requiring precise fluid control or dosing, consider pumps with high accuracy and repeatability.

Different pumps are designed for different applications and have different strengths. Some pumps are resistant to corrosion and chemical damage, while others are not. Reliability and durability are also key considerations. Laboratory pumps should be able to withstand continuous use without compromising performance or requiring frequent maintenance. It’s crucial to choose a pump that can meet the specific requirement of your applications.

2. Ease of use and controllability

- Evaluate the control options available with the pump, such as manual control, digital control, remote control, or automation compatibility.

Consider whether you need a pump with manual or automated control options. Some pumps come with advanced features such as programmable settings or remote-control capabilities, which can greatly enhance convenience and flexibility in your lab operations.

3. Maintenance and Serviceability

- Check the ease of maintenance and availability of parts for the pump. Pumps with easy maintenance can save time and money in the long run. Look for pumps that come with warranties and comprehensive customer support, including technical assistance, maintenance services and readily available replacement parts.

4. Cost and Budget

- Cost is always a consideration in any purchasing decision, but it should not be the sole determining factor. While budget constraints are a factor, investing in a high-quality pump that meets your requirements will save you money in the long run by minimizing downtime and costly repairs.

5. Regulatory Compliance

- Make sure the pump complies with any relevant industry or safety standards, especially if you’re working with hazardous materials.

6. Noise and Vibration

- Assess the noise and vibration levels of the pump, especially if it will be used in a quiet laboratory environment or near sensitive equipment.

7. Size and Portability

- Consider the physical size and weight of the pump, as well as its portability, should you need to relocate it or move it between different locations in the lab.

8. Energy Efficiency/Environmental Considerations

- Energy-efficient pumps can reduce operating costs and environmental impact.

- Consider disposal requirements.

9. Safety Features

- Ensure the pump has appropriate safety features, such as overheat protection, leak detection, and safety shut-off mechanisms.

The specific features you require in a pump will vary depending on your lab’s unique needs and the nature of your applications. By carefully considering these factors when selecting a pump for your laboratory instrumentation needs, you can ensure that you make an informed decision that aligns with your requirements while maximizing efficiency and productivity in your lab.

More Resources:

- Shop New, Used and Refurbished Pumps from GenTech Scientific’s Inventory.

- Shop pumps at our eBay store.

- TECH TIP: Removing a Pump from a 4000 QTrap

- TECH TIP: How to Disconnect an Acquity Binary Pump to Send for Repair