The wide variety of cannabis concentrates entering today’s market is only expanding with time. The cannabis industry must remain accessible to new buyers and investors attempting to understand the product’s jargon, techniques, and history. Let’s break down two of the most in-demand cannabis concentrates available on the market today.

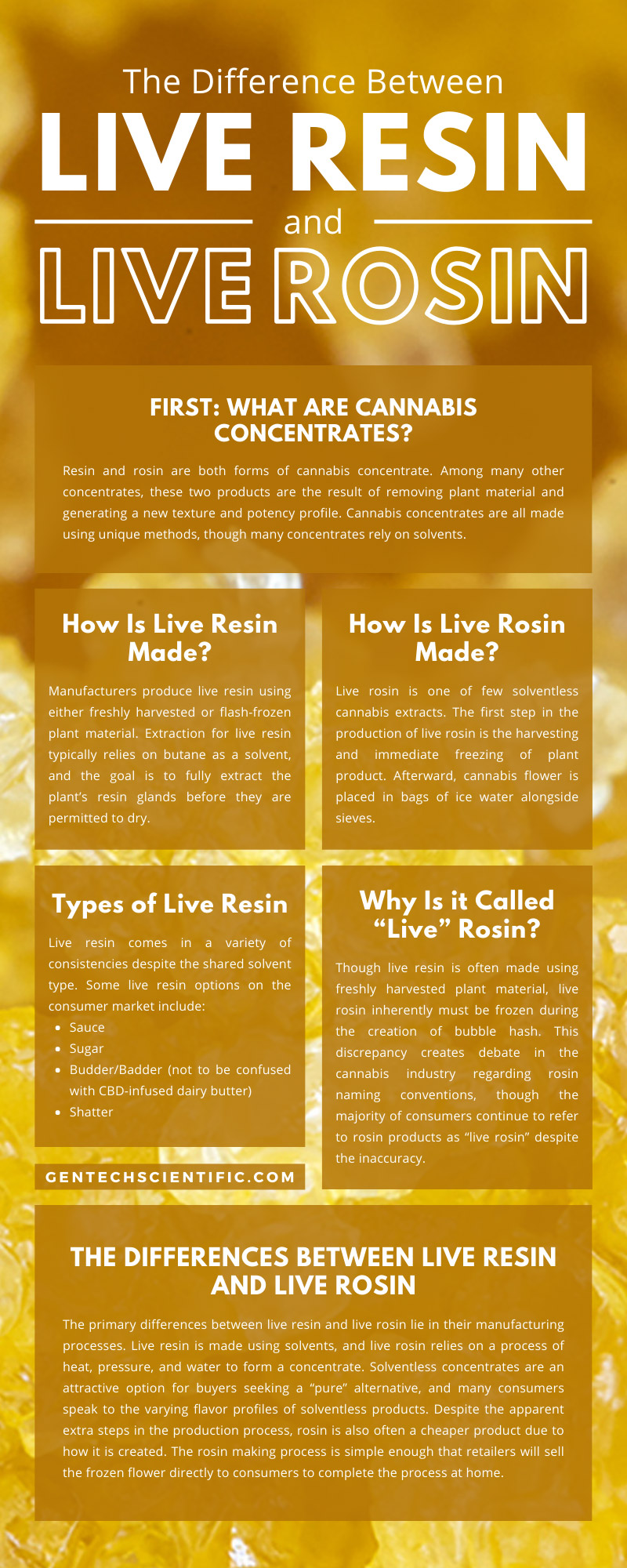

First: What Are Cannabis Concentrates?

First, it is essential to discuss the umbrella terminology manufacturers, retailers, and consumers rely on when engaging with cannabis products to understand the difference between live resin and live rosin. Resin and rosin are both forms of cannabis concentrate. Among many other concentrates, these two products are the result of removing plant material and generating a new texture and potency profile. Cannabis concentrates are all made using unique methods, though many concentrates rely on solvents.

The Purpose of Solvents

Solvents serve as the means to separate the various components of the plant and isolate the desired product. Many solvents are acceptable for cannabis extraction, though butane, propane, alcohol, and CO2 are all commonly relied on. Water, notably, can be used but is not considered a solvent for the industry’s purposes.

Once the solvent has completed its job and the plant material is removed, the solvent itself must be evaporated from the product. Cannabis products must undergo residual solvent analysis to ensure the result is high quality and meets the industry and the manufacturer’s standards.

How Is Live Resin Made?

Manufacturers produce live resin using either freshly harvested or flash-frozen plant material. Extraction for live resin typically relies on butane as a solvent, and the goal is to fully extract the plant’s resin glands before they are permitted to dry. By not curing the plant, manufacturers produce a clearer terpene profile, as well as an aroma and flavor often described as sweet and floral.

Types of Live Resin

Live resin comes in a variety of consistencies despite the shared solvent type. Some live resin options on the consumer market include:

- Sauce

- Sugar

- Budder/Badder (not to be confused with CBD-infused dairy butter)

- Shatter

Live resin is considered among the highest quality cannabis products available. Due to the use of butane, a potentially dangerous solvent, manufacturers are expected to set a higher standard for the quality of live resin products.

How Is Live Rosin Made?

Live rosin is one of few solventless cannabis extracts. The first step in the production of live rosin is the harvesting and immediate freezing of plant product. Afterward, cannabis flower is placed in bags of ice water alongside sieves. When these bags are agitated, frozen resin glands separate from the plant material and pass through the sieve. This process creates a product known as bubble hash.

Next, the collected bubble hash is placed in a freeze drier. Once finished, manufacturers use a method called pressing as well as a tool called a rosin press to extract the final product. The technique of pressing creates a sap-like consistency through a combination of heat and pressure.

Why Is it Called “Live” Rosin?

Though live resin is often made using freshly harvested plant material, live rosin inherently must be frozen during the creation of bubble hash. This discrepancy creates debate in the cannabis industry regarding rosin naming conventions, though the majority of consumers continue to refer to rosin products as “live rosin” despite the inaccuracy.

The Differences Between Live Resin and Live Rosin

The primary differences between live resin and live rosin lie in their manufacturing processes. Live resin is made using solvents, and live rosin relies on a process of heat, pressure, and water to form a concentrate.

Solventless concentrates are an attractive option for buyers seeking a “pure” alternative, and many consumers speak to the varying flavor profiles of solventless products. Despite the apparent extra steps in the production process, rosin is also often a cheaper product due to how it is created. The rosin making process is simple enough that retailers will sell the frozen flower directly to consumers to complete the process at home.

Meanwhile, live resin gains a more luxurious status than rosin, in part due to its manufacturing process. The introduction and removal of solvents require unique machinery and the technique required to create high-quality live resin increases its exclusivity. The result of the extra effort is often higher potency and a more impactful terpene and cannabinoid profile.

Aside from the product price, one unique advantage that sets rosin’s demand higher is the varied aroma and coloration of the product. Consumers express a preference for a flavor profile more reminiscent of the original plant, and though both products fill that niche on the market, rosin is thought to present a more accurate depiction in taste and smell.

Maintaining Cannabis Concentrate Quality

Both live resin and rosin are ingestible products, meaning that product safety remains of utmost importance to the industry. Maintaining cannabis concentrate quality is best done using analytical testing equipment like gas chromatography or high-performance liquid chromatography (HPLC) systems.

Analytical machines provide insight into any residual solvent present in the product when a solvent is used. This process also ensures that manufacturers are only using approved solvents that are safe for human consumption should any remain. HPLC equipment also has the ability to measure for the presence of pesticides and mycotoxins in the final product.

After product safety is confirmed, analytical machines play a key role in determining how cannabis products measure up against others. Gas chromatography instruments measure THC potency and terpenes while creating a highly accurate cannabinoid profile for each product.

Understanding the strain, power, and components of each product allows for more informed consumer decisions. This information is especially important for physicians making medical recommendations, as well as consumers buying with allergies in mind.

At GenTech Scientific, we provide a variety of services to support cannabis testing and analysis labs across the country. Our team of experienced technicians works to provide you with refurbished, certified scientific instruments from leading brands in the industry. We also proudly offer services and repairs that keep your lab operating smoothly.

Alongside instrument installation and setup, GenTech also offers customized instrument training to help your facility begin using new lab equipment with confidence. Training includes guidance on operation, troubleshooting training, advice on cannabis testing methods, and more. Browse our available systems and reach out for a quote to get started on your lab’s next upgrade.